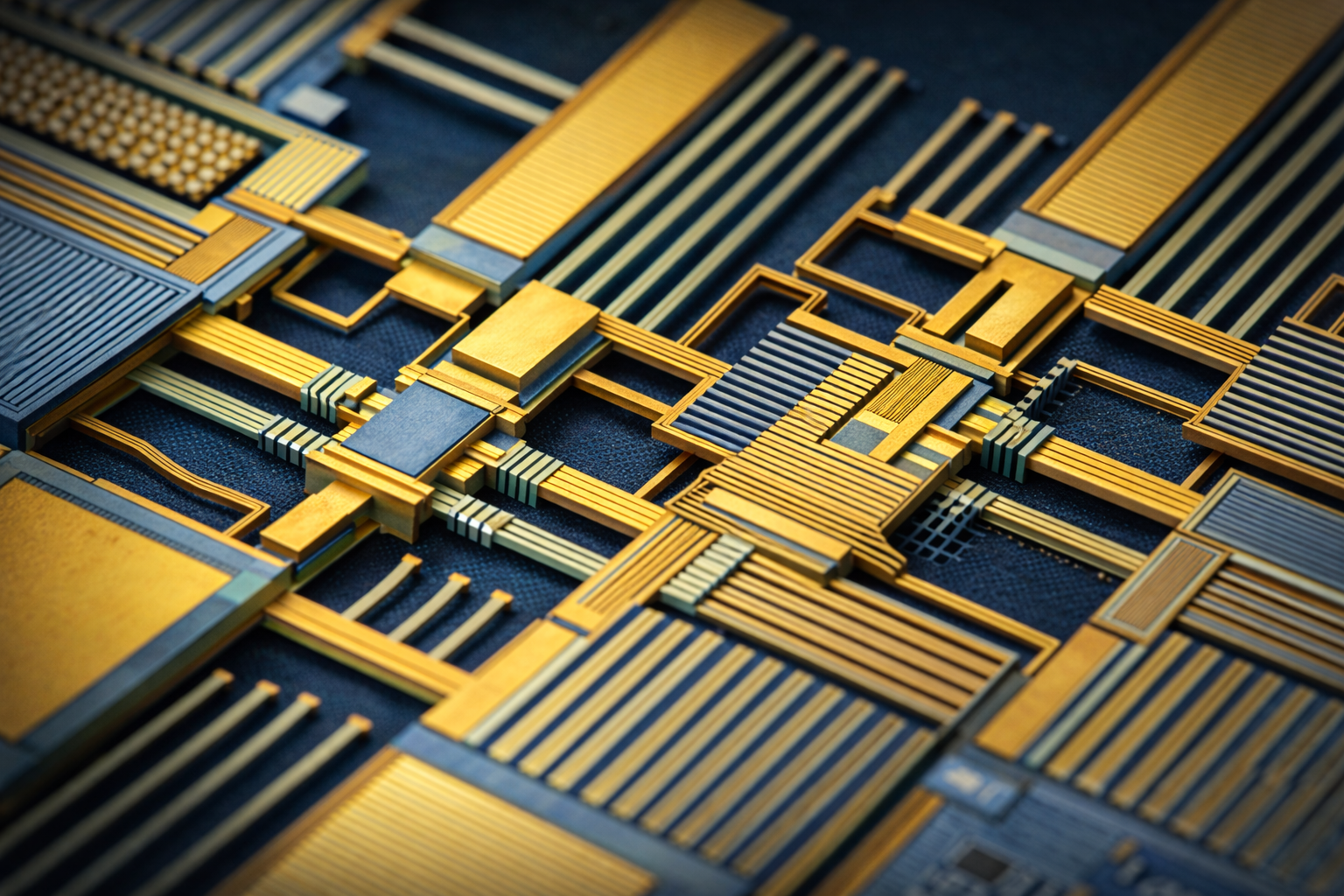

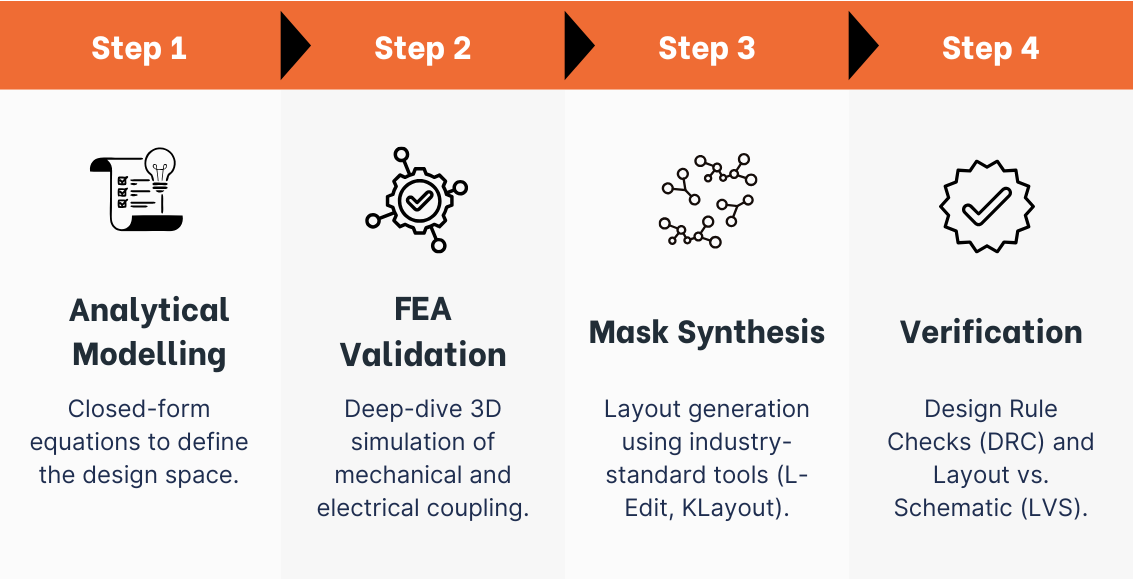

De-risk your micro-system development with high-fidelity multiphysics simulation and DRC-clean mask layouts. We turn complex transducers into manufacturable reality.

Coupled Electro-static, Piezoelectric, Thermal, and Fluidic (CFD) analysis

DRC-clean, foundry-ready layouts with optimized anchor points and stress-relief structures

Custom process flow development (Bulk vs. Surface Micromachining, SOI, CMOS-MEMS)

Monte Carlo simulations to predict how fabrication tolerances affect device performance